Gummies and Jellies

Find out here the best machines for Gummies and Jellies

Pinco S.A. – why us?

World class confectionery

Pinco SA is a manufacturing company making drying rooms for soft confectionery.

Established in the early 1970s designing drying rooms with innovative technical solutions quickly made the name of the company well known to jelly manufacturers in search of a way to improve the quality of their products. Pinco manufacture the right machinery for each single customer, targeted at its specific needs.

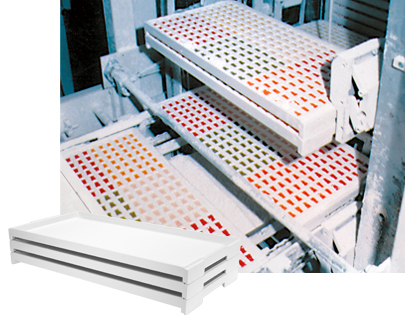

Molded Fiber Glass Tray, MFG Tray (USA), is a leading manufacturer of high strength, glass reinforced composite containers, trays, boxes, flats and totes for material handling in the confectionery, food service, plastics and electronics assembly industries, as well as in pharmaceutical processing and metalworking. The company continually develops customised solutions for specific material handling challenges and applications.

The first and best innovative solution since 25 years to prevent bad imprints and dirty trays during starch moulding production.

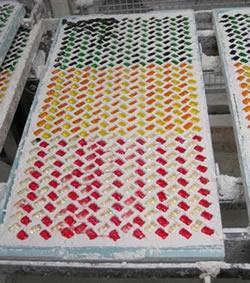

LHT Consultancy and Eagle Vision collaborated to design a solution to problems caused by poorly filled starch trays.Dirty starch trays cause many stoppages and delays on a starch moulding line.